To ensure your steam boiler is working to its optimum level it is essential that the quality of its feedwater is as pure as it can be.

The feedwater is used to produce the steam, therefore the quality of water going into the boiler will have a profound effect on the safe operation of the equipment. It is vital this is treated correctly.

Boiler blowdown, which is the removal of water from a boiler, is another essential part of a steam boilers operation. It controls the boiler water parameters, within prescribed limits, to minimize scale, corrosion, carryover, and other specific problems.

Essentially, the lower the blowdown rate, the more energy efficient your boiler is and in order to reduce the blowdown rate, the water must be high quality with the least number of impurities.

The delivery of feedwater, collection of condensate and blowdown of a boiler is essential to the most effective operation of a steam system.

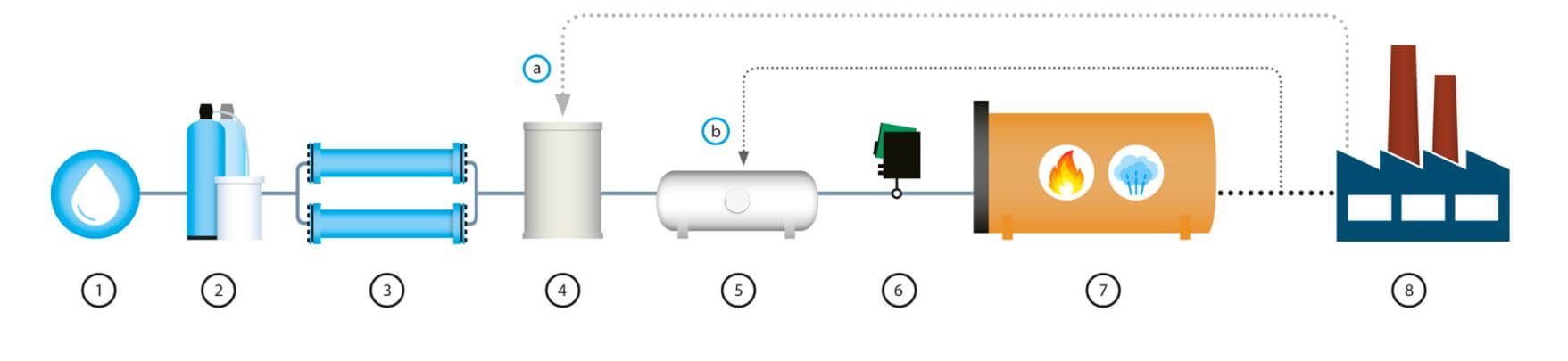

Feedwater Treatment & Dosing

Water which is fed to a boiler contains dissolved minerals and gasses which can cause serious damage and without the right water treatment, the plant will suffer from scale and corrosion.

Therefore, the quality of feedwater must be top class which means there are a few processes it must go through before entering the boiler.

The most common form of pre- water treatment is water softening to ensure water contains only non-hardness forming salts. If hardness is present in the feedwater and not controlled chemically, then scaling of the heat transfer surfaces will occur, reducing heat transfer and efficiency.

Feedwater hardness usually ranges from 0.01 to 2.0 ppm, but even water of this purity does not provide deposit-free operation. By softening the water, scaling is prevented but the content of bicarbonate of the raw water passes through the softening plant which is why another course of treatment is required.

1. Raw Water 2.Softening 3. Demineralisation 4.Water Tank 5.Degassing 6.Dosing Pump 7.Steam Boiler 8.Production